Comprehensive strength in manufacturing

- Top

- Izumi’s strength

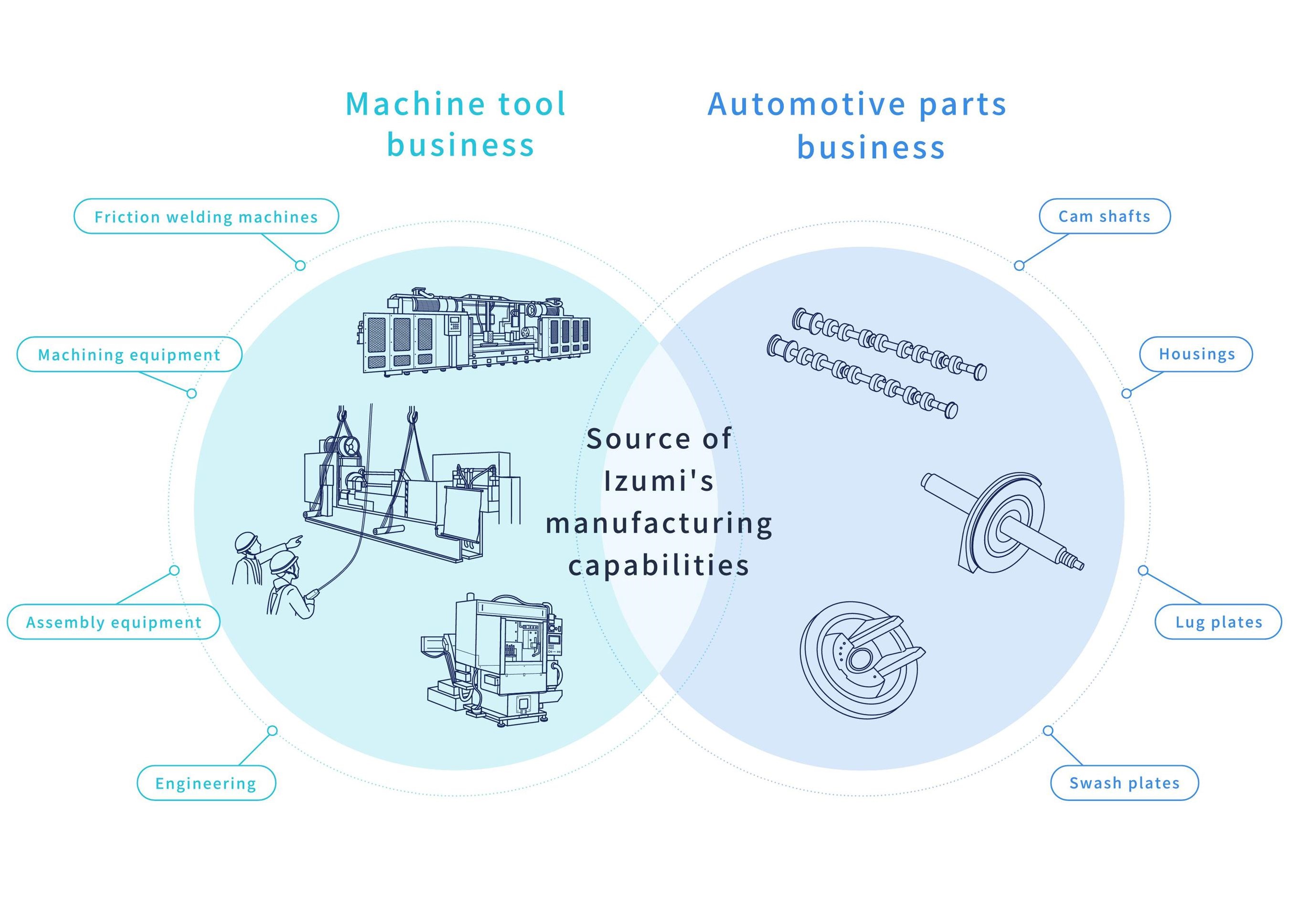

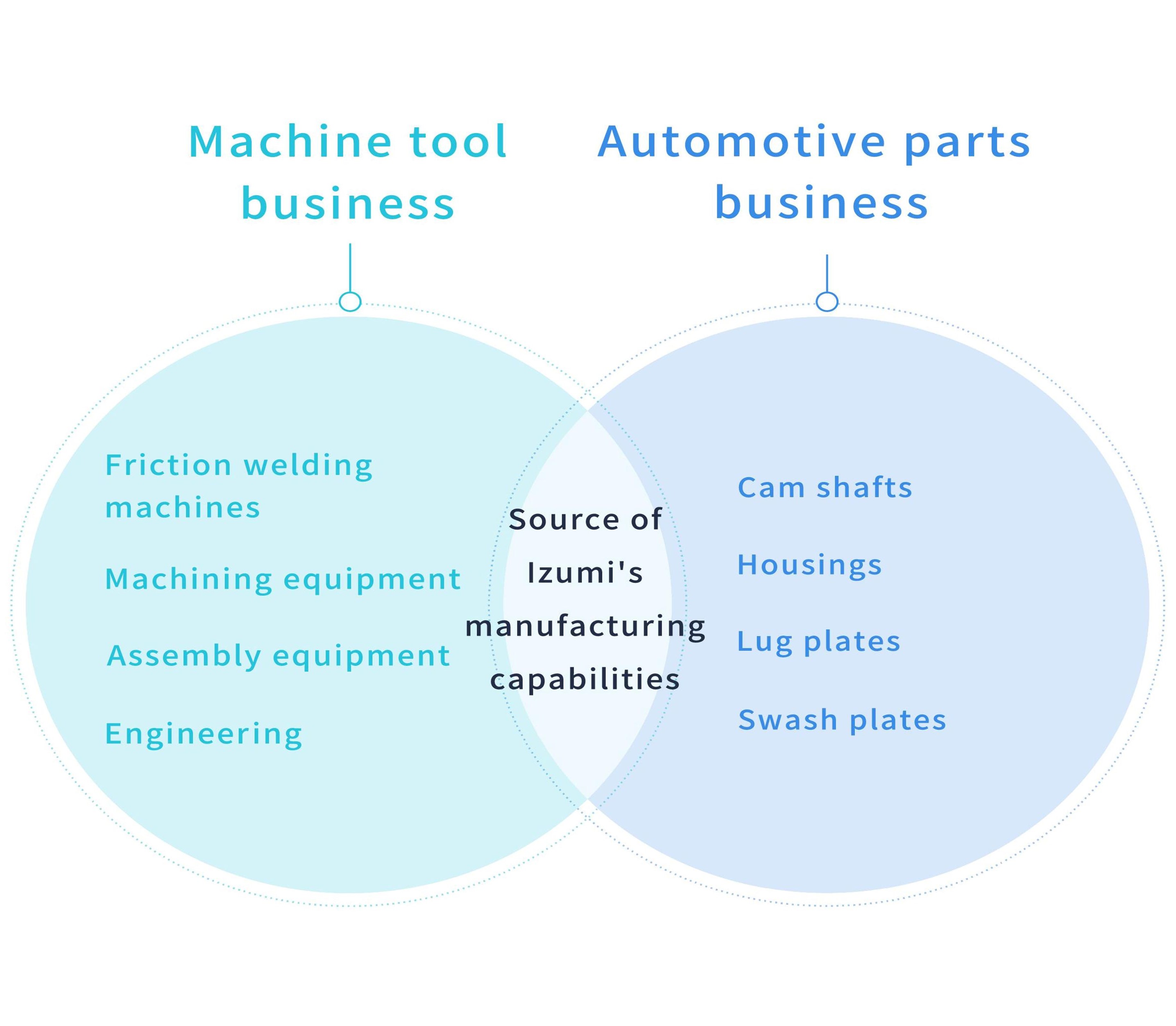

“Comprehensive strength in manufacturing” through the production of machine tools, the installation of production lines, to the mass production of automotive parts

Broadly speaking, we have two businesses.

The first is “machine tools.” We develop, design and produce machine tools, install them efficiently, and provide engineering services that make them function as a production line.

The other is “automotive parts business.” We are continuing to produce each and every one of a huge quantity of products numbering in the millions or tens of millions each year under strict quality standards, at convincing prices and by their determined deadlines.

We have pursued the synergies of these businesses at all times. We design our easy-to-use, high-performance machine tools with understanding of the difficulties of mass production, and they can be realized precisely because we can verify them through actual operation. Our high quality, low-price automotive parts can be realized because of our company’s equipment. We are “a manufacturer and also a user” and we are striving to improve our “Comprehensive strength in manufacturing” while using this advantage to the maximum.

- Machine tool business

- Automotive parts business

-

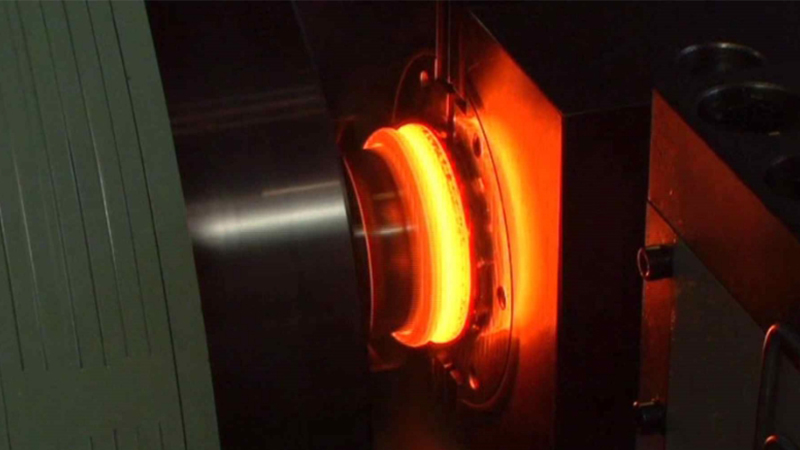

As a pioneer of friction welding machines. As the number one manufacturer.

In our machine tool business, we develop and manufacture various processing equipment and assembly equipment such as friction welding machines and machining centers, and provide high value added production systems.

Our friction welding machines, in particular, which apply “pressure welding” joining technology, have the top market share domestically (company estimate) and cutting-edge technology that attracts attention globally.

The company that brought friction welding technology to Japan for the first time and succeeded in the development of the first domestically-produced friction welding machines was TOYOTA INDUSTRIES CORPORATION, one of our shareholders.

In 1997, we succeeded to that technology and know-how across the board and poured our energies into research and development thereafter. We provide customers with the optimum solutions through the development, design and manufacture of machine tools.ADVANTAGE

Technical strength that boasts a high advantage

We have implemented development, design and manufacture as a pioneer of friction welding machines, and pursued their potential thoroughly. Pressure welding is a technology that uses the thermal energy generated by friction to bond objects and has high advantages over welding in terms of quality, productivity, cost and the environment. We are convinced that its use will expand with certainty from now on.

VALUE

We want to spread new value in the market

In such circumstances, we believe that one of our missions is to spread the superior performance of friction welding technology more and to expand the market itself. We will strive for the creation of new value in machine tools, including specialized machines and assembly machines.

NEEDS

Responding to various needs

We respond to customers’ friction welding needs through the implementation of welding studies and trial production using test machines installed at our friction welding development center. In addition, we develop state-of-the-art machines, including machines with a “phase adjusting function,” which we were the first company in the world to succeed with in development by adopting an electric servo method. We are also working positively and boldly on technology development in anticipation of the needs of customers.

-

Making the cars of the world more comfortable and safer.

Automotive parts numbering in the tens of thousands. We manufacture the engine cam shafts said to be especially important safety related parts, and the swash plates and lug plates installed in car air-conditioning compressors. Because these are important parts related to the basic performance and comfort of cars, certain quality is required. In addition, we make efforts day by day while responding to customer needs for low-cost, stable product provision.

ABILITY

Pride as a main supplier

The automobile industry is the foundation of the Japanese economy. We are aware of the weight of responsibility to deliver each and every one of a huge quantity of products numbering in the millions or tens of millions each year under strict quality standards, at convincing prices and by their determined deadlines. We use our stable production capacity based on a three-factory system at Head Office, Ishihama and Kitasaki to respond to just-in-time requests.

QUALITY

The belief that there is no goal in quality improvement

High accuracy, certain quality, elimination of defects and the reduction of costs. We promote continuous activities because of our belief that “there is no end to quality improvements” in regard to the challenges above demanded of automotive parts. We use all means and all opportunities to improve processing, processes and equipment, including quality improvement sub-committees and independent study meetings, improvement proposals by all members, creative ingenuity presentations, etc., and we live and breathe that attitude as the culture of the company.

COST

Demanding better quality and cost reductions

Ceaseless efforts towards quality improvements and cost reductions extend to our headwaters. We are positively involved in simultaneous engineering (SE) activities from the standpoint of manufacturing from development and design and the production technology stage, which connects to more fundamental quality improvements and cost reductions. Moving forwards even a step or half a step for the sake of quality and costs. We will aim for further evolution without sparing any effort to that end.

- Machine tool business

- Automotive parts business