History

- Top

- Corporate information

- History

Founded in 1946, the following introduces the company’s history of inheritance of technology and improvement through advanced technology, and the trail of its uncompromising challenges.

1946

Founded Nishiyama Seisakusho (predecessor of Izumi), in Shinkawa-machi, a suburb of Nagoya.

1948

Developed music boxes and started limited marketing of them.

1949

Incorporated and changed name to Izumi Machine Manufacturing Co., Ltd..

1952

Built Atsuta Plant

Started manufacturing parts for buses, scooters and small trucks for Mitsubishi Heavy Industries, Ltd.

1960

Started marketing (designing and manufacturing) specialized manufacturing equipment.

1964

Oshima Industries Co., Ltd., established, the predecessor of SKE Co., Ltd. (merged in 2009)

Started designing and manufacturing welding jigs

1973

New factory built in Obu City. All equipment from Shinkawa and Atsuta factories moved there.

Toyoda Automatic Loom Works, Ltd (current TOYOTA INDUSTRIES CORPORATION) consigned manufacturing of friction welding machine to Izumi.

1982

Started trial production in friction welding laboratory as part of machine tool business.

Automotive parts electrodeposition painting line completed for MITSUBISHI MOTORS CORPORATION and starts production.

1993

Oshima Industries Co., Ltd and Toyoda High Engineering Co., Ltd merge to become SKE Co., Ltd.

Became a wholly-owned subsidiary of Toyoda Automatic Loom Works, Ltd

1995

Toyoda Automatic Loom Works, Ltd starts capital participation

Started production of car air-conditioning compressor swash plates for Toyoda Automatic Loom Works, Ltd.

Started marketing of vertical lathes.

1997

Control of friction welding machine business transferred from Toyoda Automatic Loom Works, Ltd

1998

Started marketing NC center broaching machines

1999

New factory built in Kitasaki. Expanded production of parts for car air-conditioning compressors

2002

Acquired ISO14001 certification

2003

Started marketing vertical friction welding machines

2004

SKE, Logistech and Tokai System merged to become a general engineering company.

2005

Acquired ISO9001 certification (Kitasaki Factory)

Started production of suspension members (automotive parts for TOYOTA MOTOR CORPORATION)

Started production of lug plates for car air-conditioning compressors

2006

Started production of engine cam shafts

2007

Became a wholly owned subsidiary of TOYOTA INDUSTRIES CORPORATION.

2008

Control of Ishihama Factory transferred from TOYOTA INDUSTRIES CORPORATION, expanded automotive parts machining business.

2009

Merged with SKE Co., Ltd

2010

Achieved cumulative production of 100 million swash plates for car air-conditioning compressors.

2016

Started marketing of new type of vertical lathes.

2017

Achieved cumulative sales of 1,000 machine tools.

2018

Ended production of suspension members (automotive parts for TOYOTA MOTOR CORPORATION)

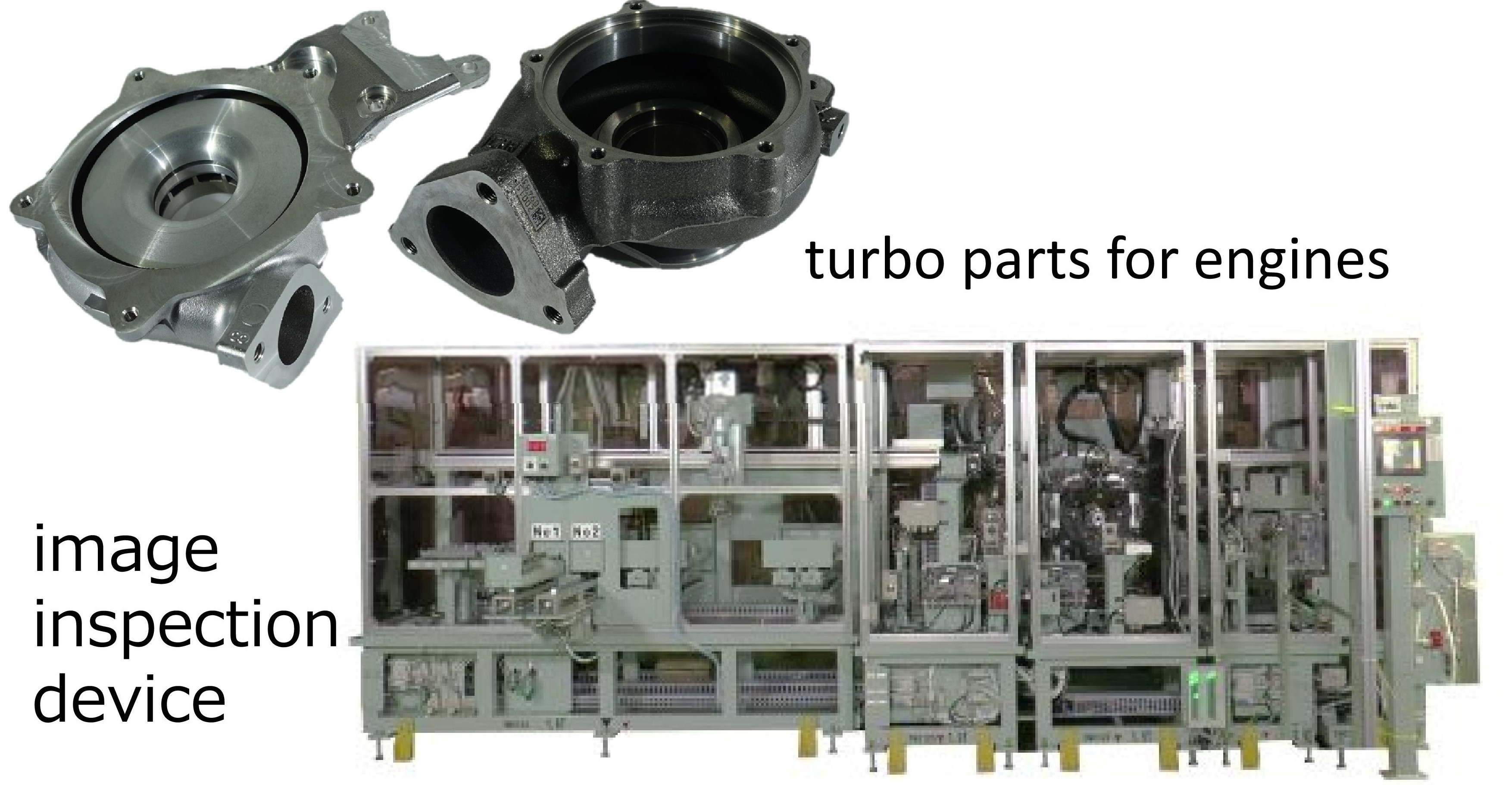

2020

Started production of turbo parts for engines.

Image inspection device development

2021

Started marketing of horizontal lathe

2024

Aichi Brand certification